In a world of quick fixes and throwaway objects, 3D printed lamps stand apart.

They aren’t churned out by the thousand or locked into a single mold. They’re crafted layer by layer, in a process that respects both form and function.

More than just a new way of making things, 3D printing is a statement: that good design should be adaptable, sustainable, and personal.

And nowhere is that clearer than in the way 3D printed lamps transform everyday lighting.

Let’s explore why this shift matters - and how 3D printing is quietly reshaping how we bring light into our lives.

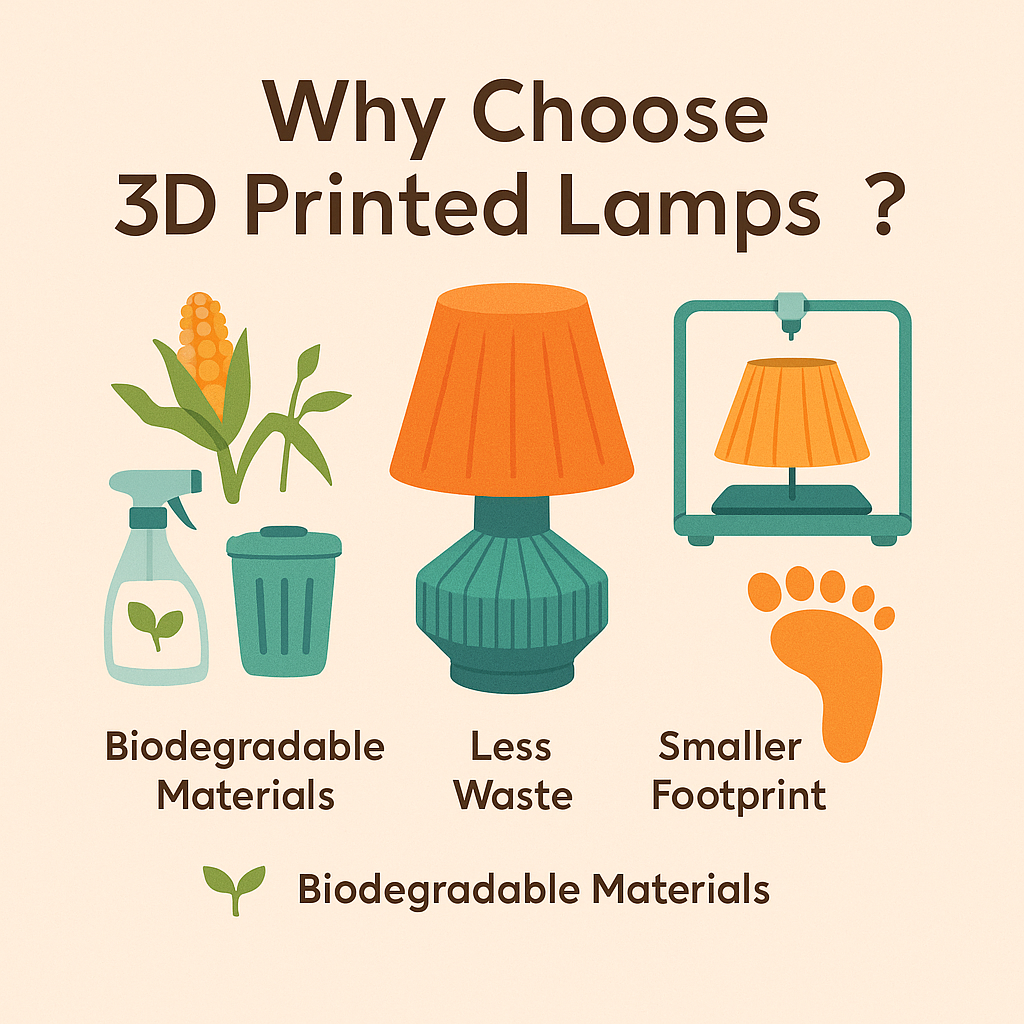

A Greener Approach to Lighting

Sustainability isn’t just a buzzword when it comes to 3D printing.

Unlike conventional plastic lamps, which rely on large-scale injection molding and fossil-fuel-derived plastics, 3D printed lamps typically use PLA - a material made from renewable resources like corn starch and sugarcane.

PLA is biodegradable in industrial composting environments, making it a more mindful choice for anyone who wants to reduce their impact.

But the sustainability story doesn’t stop at materials.

Because 3D printing builds each piece layer by layer, it only uses as much material as the design calls for. There’s no need for big, expensive molds that are used thousands of times — and then thrown away.

This small-batch production model means:

- Less waste | no need to overproduce or create unnecessary stock

- Less energy | fewer resources spent on huge, centralized manufacturing

- Smaller carbon footprint | localized production cuts down on shipping

For anyone looking to live a little lighter - and invest in home pieces that reflect that mindset - 3D printed lamps are an easy, beautiful step forward.

Design Without Limits

What sets 3D printed lamps apart isn’t just the material - it’s the freedom of form.

Traditional manufacturing often limits designers to shapes that are easy to cut, mold, or cast. 3D printing? It opens up a playground of possibilities.

Imagine:

- Intricate patterns and textures that feel organic and alive

- Soft curves and complex geometries that would be impossible with conventional methods

-

Ribbed surfaces and layered lines that catch and scatter light in unique ways

These aren’t just design flourishes - they’re functional details that affect how the light spreads, how shadows play on your walls, and how the lamp feels to touch.

For the modern home, 3D printing means you’re no longer stuck with the same cookie-cutter lamp shapes. Instead, you’re choosing pieces that feel personal, like small sculptures that also happen to glow.

From Prototypes to Personal Pieces

One of the biggest hidden strengths of 3D printing is the ability to test, refine, and perfect designs without waste.

Traditional lamp-making requires huge commitments to a single mold - any change means starting over, with a new mold, new costs, and more material waste.

With 3D printing, designers can:

- Tweak shapes and proportions without starting from scratch

- Refine how the shade diffuses light until it feels just right

- Test multiple sizes and finishes before deciding on the final piece

This ability to iterate in real time leads to designs that are more thoughtful - not just pretty, but designed to work beautifully in real homes.

The result? A lamp that doesn’t feel generic or rushed, but considered and crafted.

And because there’s no need for huge runs of identical pieces, even small studios can create limited editions or custom variations - perfect for those who want a light that feels like it’s theirs alone.

Light, Layered & Modular

3D printing isn’t just about the final shape - it’s about how that shape can change and adapt.

Many 3D printed lamps are designed with modular thinking: bodies and shades that fit together, changeable and swappable, giving you control over the final form.

Modular lighting isn’t just a design trend - it’s a way to live more intentionally:

- Reconfigure the lamp for a new mood | softer shade for quiet evenings, taller shape for dinner parties

- Adapt to new spaces | one lamp that works in your living room, your desk, or your bedside

- Keep it fresh | change the style without buying an entirely new light

The precision of 3D printing means these modular parts fit perfectly, creating a satisfying snap that feels just as good as it looks.

It’s a quiet reminder that your home should be able to change as easily as you do.

Small-Batch, Big Impact

There’s something special about an object that hasn’t been mass-produced.

When a lamp is 3D printed in small batches, it feels more intentional - more like a piece of art than just another product on a shelf.

Small-batch production:

- Keeps quality high | each piece is inspected, not rushed

- Supports local makers | often produced in small workshops or design studios

- Reduces the environmental toll of huge container ships moving identical goods across oceans

It’s a different mindset - one that values care, patience, and the idea that less can truly be more.

Where Muvelo Comes In

At Muvelo, we believe lighting should be more than just functional - it should move with you.

That’s why we embraced 3D printing to create our first collection, the Vaari portable lights.

Each Vaari is made of 3D printed parts that:

- Snap together seamlessly | no tools, no fuss

- Change their shape and height | adapt to the moment, the mood, and the space

- Feel alive to the touch | with the natural ridges and soft matte finishes that only 3D printing can offer

Vaari isn’t just about light - it’s about rhythm. About giving you the freedom to shift, swap, and shape your own atmosphere, one layer at a time.

Because in the end, good design doesn’t just sit still.

It glows, it moves, and it belongs to you.

Explore the difference at www.muvelo.in