Design isn’t just about form. It’s about responsibility.

At Muvèlo, we believe beautiful things should also be built with care, for the planet, and for the people who use them. That’s why every Vaari light is made using sustainable, small-batch 3D printing.

Here’s how we do it, and why it matters.

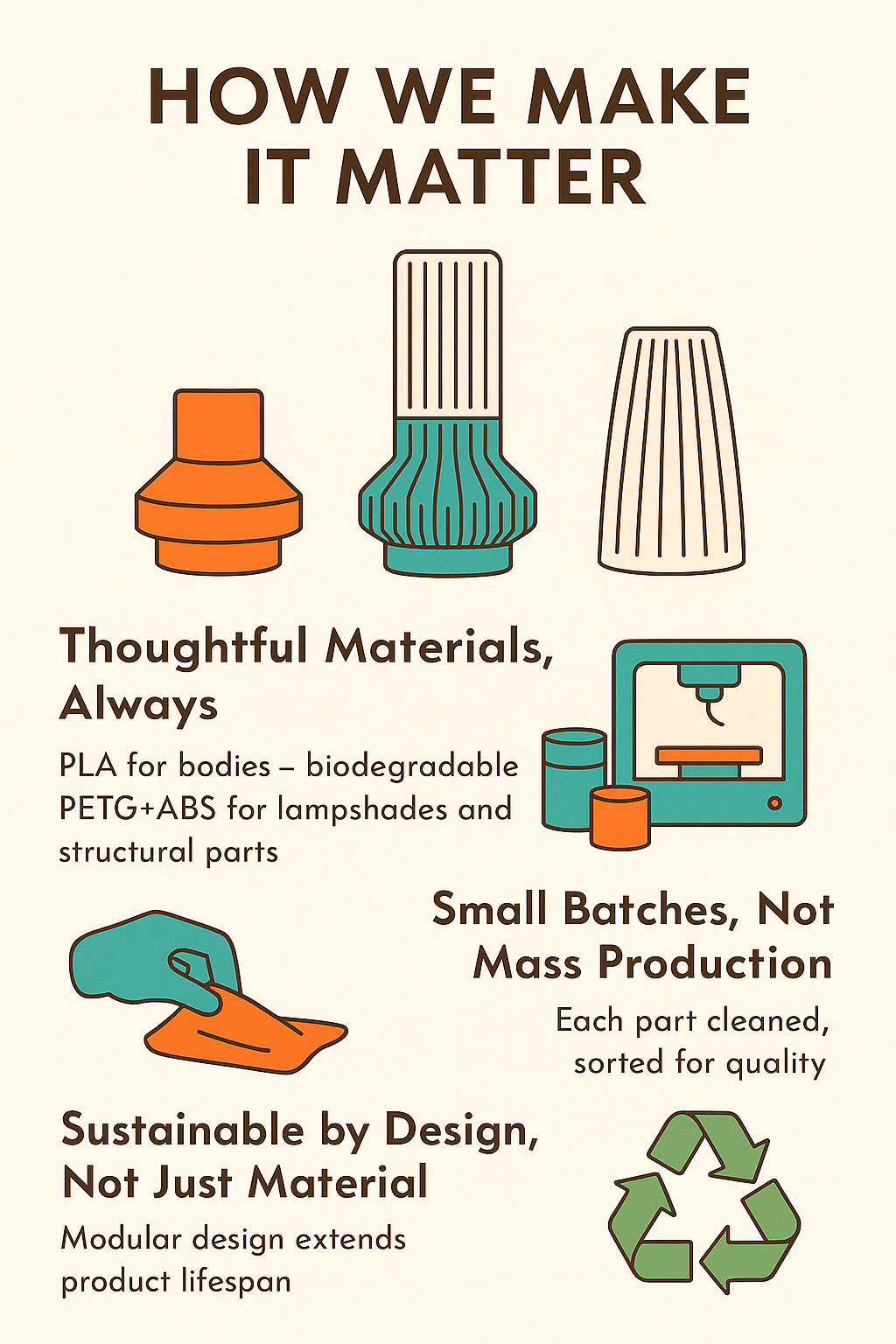

1. Thoughtful Materials, Always

We don't believe in using “eco-friendly” as a buzzword. For us, material selection is a technical, aesthetic, and ethical decision, every single time.

PLA for the Body

PLA (Polylactic Acid) is our primary material for the Body. It’s a plant-derived polymer made from renewable sources like corn starch and sugarcane.

Why we use PLA:

-

It’s biodegradable in industrial composting systems (unlike most plastics)

-

It prints with high visual clarity, which is perfect for detailed, ribbed designs

-

It has a soft, matte texture that aligns with our aesthetic language, natural, warm, and tactile

PLA also reinforces our belief in low-impact production. It’s not perfect, it still requires controlled disposal, but it’s a step forward in reducing dependence on petroleum-based plastics.

PETG for the Lampshade

PETG (Polyethylene Terephthalate Glycol-modified) is used for all Lampshades.

Why PETG?

-

It offers excellent optical clarity, which helps diffuse the 3000K warm LED evenly

-

It is impact-resistant and durable, making it ideal for portable use

-

It holds its shape and finish over time, resisting discoloration or brittleness even in varied indoor conditions

We’ve chosen PETG over acrylic or polycarbonate because it strikes a balance between strength, flexibility, and recyclability. It's also safer to handle during the 3D printing process.

ABS + PETG for the System

The System, which houses the battery, LED, switch, and controller, requires structural integrity and heat resistance.

We use a mix of:

-

ABS: Strong, reliable, and able to withstand drops from up to 4 feet (as tested). It also resists deformation from the slight heat generated by electronics.

-

PETG: For areas that benefit from a more flexible snap-fit without cracking, especially in the lid and fastening components.

This material logic ensures each part performs optimally without overengineering or waste. Our goal: the right material in the right place, nothing more, nothing less.

2. Small Batches, Not Mass Production

Most lighting brands focus on scale. We focus on precision.

Muvèlo runs a batch-based production cycle where we 3D print and finish products in small lots. This gives us control not just over inventory, but over quality, flexibility, and waste reduction.

Why small batches?

-

Reduces overproduction – We only make what’s needed, reducing excess inventory and raw material use

-

Ensures consistency – Each print is monitored, adjusted, and inspected throughout the cycle

-

Enables customization – We can tweak lampshade patterns, test new forms, or roll out limited-edition bodies without needing to reset a factory line

-

Supports experimentation – We believe in form exploration. Small batches allow us to evolve designs faster, with feedback built into the loop

This model is slower than mass production, but that’s the point. We’re not here to flood the market. We’re here to build well, not just build more.

3. Hand-Finished with Intention

After the machines stop, our hands take over.

Each Muvèlo light is handled, refined, and assembled manually at our Pune studio. No part goes directly from printer to box.

The finishing process:

-

Support removal: We manually remove any 3D print supports without damaging detail

-

Surface cleanup: Minor imperfections are sanded with fine abrasives to preserve form while smoothing edges

-

Fitting check: The modular parts are tested for fit tolerance, ensuring that bodies and shades snap in without being too loose or too tight

-

Electrical assembly: The battery system is hand-soldered, encased, and tested for charging function, switch response, and LED brightness

-

Final polish: The light is cleaned, dusted, and checked under real lighting conditions before it’s packed

This process takes longer, but it ensures consistency you can feel—in the click of a part, the stability of a base, and the evenness of a glow.

Hand-finishing also allows us to honor the craft behind every light. We’re not pushing products down an assembly line. We’re building each piece to matter.

4. Sustainable by Design, Not Just Material

A sustainable product isn’t just about what it’s made from. It’s about how it’s made, how it’s used, and how long it stays useful.

Here’s how we design for sustainability:

-

Modularity reduces waste: If a lampshade cracks or a body feels outdated, just replace that part. Not the whole product.

-

Durability extends product life: PETG and ABS components withstand wear, drops, and regular use, reducing how often things are discarded or replaced.

-

Local production minimizes emissions: All Muvelo lights are designed, printed, assembled, and shipped from India—no overseas manufacturing, no container ships.

-

Made-to-order mindset: We keep only a limited rolling stock. Most prints are created close to purchase, meaning energy is only used where it’s needed.

And most importantly: our designs are meant to grow with you.

Instead of being tied to a single look, your Vaari light can change over time. Swap parts. Try new shades. Adapt your light as your life shifts.

This flexibility is an antidote to planned obsolescence, a core principle in Muvelo’s mission.